Heat Treatment Of Aluminum

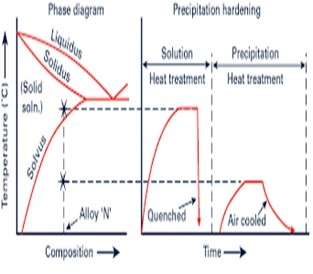

Heat treatment of aluminum. When the term is applied to aluminum alloys howev-. Aluminium and its alloys are used in a variety of cast and wrought forms and conditions of heat treatment. It is different in so much as the solution as treatment which involves heating the aluminium alloy up to its appropriate solution temperature followed by quenching rapidly this makes the alloy extremely soft.

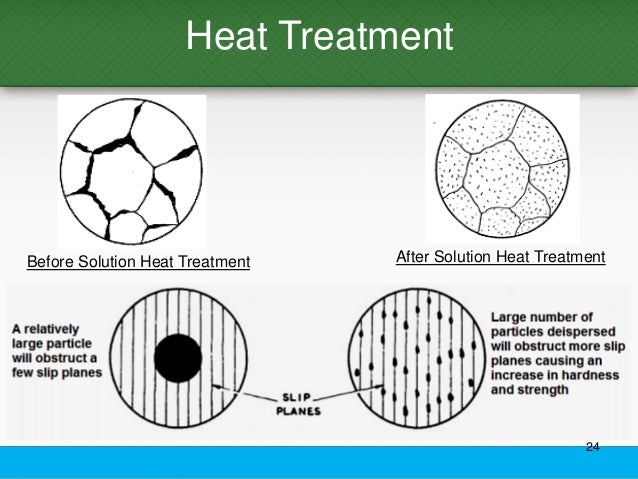

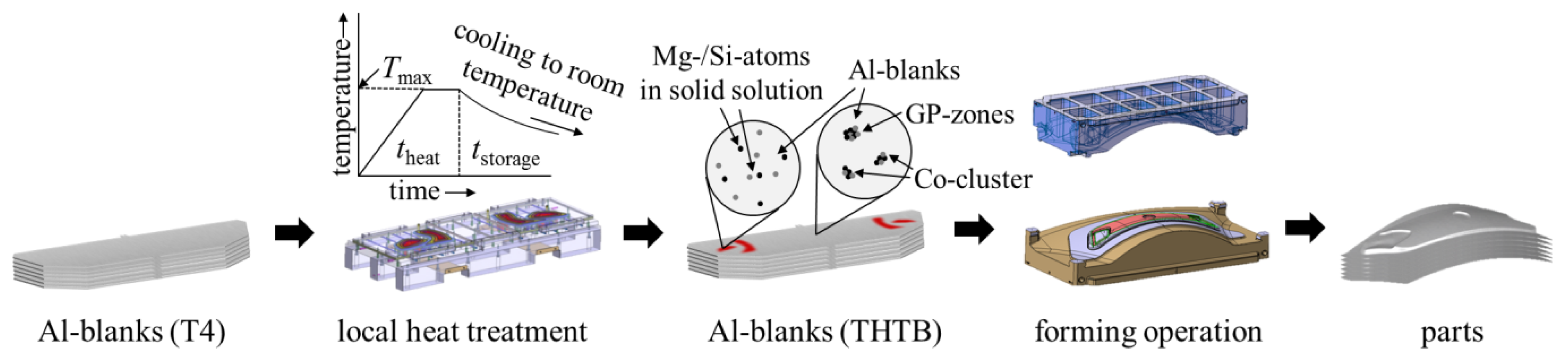

Aluminum alloys are subject to work hardening also known as strain hardening. Therefore heat treatments which are commonly applied to conventionally produced aluminium alloys may need to be recalibrated in terms of the holding temperatures and durations or even completely reformulated to obtain satisfactory microstructural modifications and consequently mechanical properties. Solution heat treatment involves heating the aluminum and alloys to a temperature slightly below the eutectic melting temperature.

Preheating or homogenizing to reduce chemical segregation of cast structures and to improve their workability Annealing to soften strain-hardened work-hardened and heat treated. This requires heating the material close to near the eutectic temperature and holding the material at temperature long enough to allow close to complete solid solution. Heat Treating of Aluminum Alloys HEAT TREATING in its broadest sense refers to any of the heating and cooling operations that are performed for the pur- pose of changing the mechanical properties the metallurgical structure or the residual stress state of a metal product.

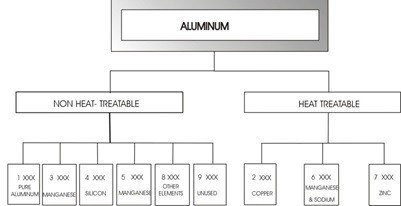

In heat treatable alloy systems like 7XXX 6XXX and 2XXX the al-loying elements show greater solu-bility at elevated temperatures than. The process of aluminium solutionizing treatment is slightly different to that of steel heat treatment. Applied in order to analyse a wide range of heat treatment parameters applied at an actual EN AW 6082 aluminum for - ged components.

Upon heating the elements in the alloy dissolve into a solid solution and are held there due to the quench. T5 heat treatments are expected to reduce the typical sur-face recrystallization induced by the high solubilization temperature while the use of real automotive parts is a fun -. AlSi10Mg alloy made by conventional casting is normally subjected to a T6 heat treatment in which solution treatment is carried out at around 530C followed by ageing at temperatures in the range 150180C with a view to achieving precipitation hardening by via Mg2 Si.

Types of Aluminum Heat Treatments Annealing. Homogenizing is used to redistribute the precipitating elements more evenly throughout an aluminum part. Solution heat treatment develops the maximum amount of solute into solid solution.

Strain hardening occurs when. The demand for aluminium grows rapidly because of its unique combination of properties which makes it becomes one of the most versatile of engineering and construction material 1-3.

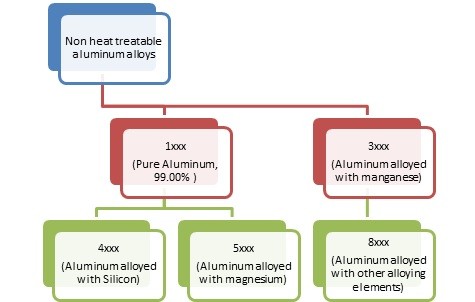

Aluminum Heat Treating Aluminum Solution Heat Treat-ing Aluminum alloys are classified as either heat treatable or not heat treatable depending on whether the alloy responds to precipitation hard-ening.

Solution aluminum heat treating is typically done in a range of 850 1050 F followed by rapid quenching in water. Solution heat treatment involves heating the aluminum and alloys to a temperature slightly below the eutectic melting temperature. At that point the basket containing the parts is dropped into a quench tank. Aluminium and its alloys are used in a variety of cast and wrought forms and conditions of heat treatment. AlSi10Mg alloy made by conventional casting is normally subjected to a T6 heat treatment in which solution treatment is carried out at around 530C followed by ageing at temperatures in the range 150180C with a view to achieving precipitation hardening by via Mg2 Si. The Quenching and Aging Heat Treatment Process The process of taking a 6061 aluminum part in O condition to a stronger more durable condition begins by heat treating the parts at 985 degrees Fahrenheit for an hour in a drop bottom furnace. Aluminum Heat Treating Aluminum Solution Heat Treat-ing Aluminum alloys are classified as either heat treatable or not heat treatable depending on whether the alloy responds to precipitation hard-ening. T is the heat treatment aluminum alloy temper which is different from F O H temper It is suitable for products that are stable after or without work hardening after heat treatment. Types of Aluminum Heat Treatments Annealing.

Solution heat treatment develops the maximum amount of solute into solid solution. It is different in so much as the solution as treatment which involves heating the aluminium alloy up to its appropriate solution temperature followed by quenching rapidly this makes the alloy extremely soft. When aluminum undergoes quenching it is typically heated to a temperature way above its recrystallization. The process of aluminium solutionizing treatment is slightly different to that of steel heat treatment. Types of Aluminum Heat Treatments Annealing. Heat Treating of Aluminum Alloys HEAT TREATING in its broadest sense refers to any of the heating and cooling operations that are performed for the pur- pose of changing the mechanical properties the metallurgical structure or the residual stress state of a metal product. Therefore heat treatments which are commonly applied to conventionally produced aluminium alloys may need to be recalibrated in terms of the holding temperatures and durations or even completely reformulated to obtain satisfactory microstructural modifications and consequently mechanical properties.

.jpg)

Posting Komentar untuk "Heat Treatment Of Aluminum"